The following article features excerpts from our expert webinar series, Slide Savvy with Fernando. Fernando Chang, IMG, a pathologist assistant renowned for his expertise in frozen section analysis, addresses some common issues with frozen section slide preparation and introduces tips for freezing, handling and sectioning that will empower you to create high quality slides that help save lives.

Preparing quality frozen section slides is crucial for getting the most use out of available donor organs and helping save lives, but getting them right requires practice and a finely tuned process.

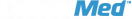

One issue that can arise is the appearance of artifact – such as shatter and Venetian blind (or chatter) – that can obscure critical tissue details, complicate the interpretation process and delay urgent medical decisions.

At first glance, shatter and Venetian blind artifact can have a similar appearance, but according to CompuMed’s lead pathologist assistant, Fernando Chang, IMG, they can have different causes. “While we can see the same horizontal pattern, it may not have the same origin,” he says.

Fernando breaks down the key differences between the two and shares two simple steps to enhance your frozen section process.

Shatter Artifact: How to Identify & Prevent It

Shatter artifact looks just like its name suggests.

“Shatter is a problem in sectioning where you see the same thing that happens when you break glass,” says Fernando. “It breaks into a lot of tiny fragments.”

These fragments may appear as horizontal lines or bands with spaces between them. The issue is caused by water within the donor organ tissue sample. It freezes into ice crystals when exposed to an overly cold block. The ice crystals then break apart when they meet the force of the sectioning blade, resulting in shatter artifact.

“We know water can be detrimental to frozen section slide preparation, but we also know that water is essential to human tissue,” says Fernando. “We need to learn how to work with it.”

The key to preventing shatter artifact lies in controlling the block’s temperature. Ideally, it should stay between -17 and -18 degrees Celsius.

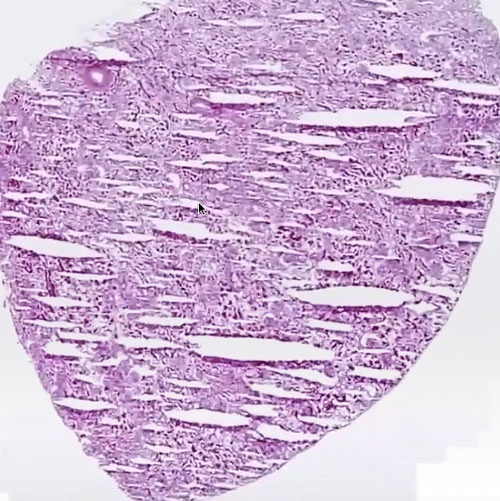

This can be monitored by evaluating an initial section or using a temperature gun. If the block is too cold, warming it slightly with your [gloved] thumb can help.

“You place your thumb on the block and count to five or 10,” says Fernando. “Having a blade next to your thumb is not ideal, but as long as you’re careful, it is effective.”

After warming the block, try another section. If the sample crumples, the block is probably too warm; if it remains flat, you’ve likely achieved the ideal temperature to prevent shatter.

Venetian Blind (Chatter) Artifact: How to Identify & Prevent It

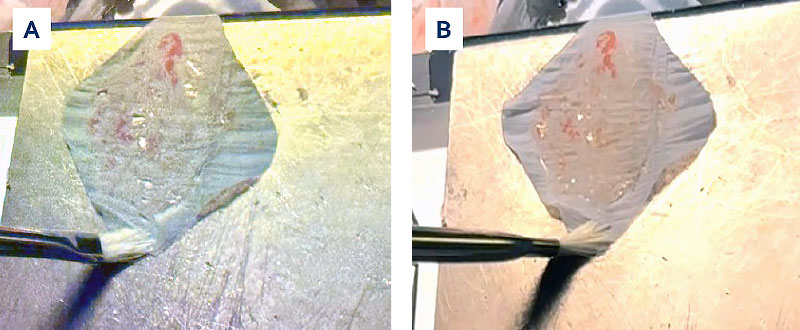

While Venetian blind or chatter artifact can also stem from a cold block, its wavy pattern is more often a result of the movement of mechanical parts within the system.

“These sections are being cut at 5 microns. A micron is one-thousandth of a millimeter, and moving parts cannot be allowed at this extremely tiny thickness,” says Fernando. “If something is moving and it’s not supposed to be, it’s going to give us a problem.”

You can help prevent chatter with basic daily maintenance of the cryostat. Check all parts – such as knobs, screws and levers – for tightness and ensure you’re maintaining proper settings. For example, the blade should typically be set at a five-degree angle. If the angle is off, the blade can jump, creating a wavy horizontal pattern.

Fernando recommends scheduling preventative maintenance for your cryostat every six to 12 months. Additionally, you may consider investing in a backup cryostat to help prevent workflow disruptions, planned or otherwise.

“During maintenance, the cryostat is going to be unplugged, its parts are going to be at room temperature, and it’s going to be out of service for at least six to eight hours, maybe even from one day to another,” says Fernando. “That’s why I recommend having two cryostats. If one fails, the other is there as a backup.”

In Conclusion: Check Your Checklist

Shatter and Venetian blind artifact can render slides unusable. Help prevent these issues by incorporating these two straightforward steps into your in-house frozen section process:

- Monitor the temperature of the block, aiming for -17 to -18 degrees Celsius.

- Perform basic daily maintenance of your cryostat and schedule it for preventative maintenance every six to 12 months.

Fernando Chang IMG

Lead Pathologist Assistant – Surgical Pathology Department

Pathology and Laboratory Medicine at University Hospital Newark NJ

Rutgers Medical School

Summit Health

Atlantic Health Care System

RWJ Barnabas Healthcare system

Drawing from methodologies pioneered by the late Dr. Stephen Peters, Fernando collaborates with the Rutgers NJMS Pathology Residency program main surgical pathology and autopsy rotation at University Hospital. Here, he imparts innovative techniques in Anatomic Pathology Rotation, Frozen Sections, and the utilization of Telepathology Aperio Scan Scope. With more than 17 years of experience, Fernando has a wealth of expertise in working closely with OPOs.

More Frozen Section Resources

- Did you find this helpful? For more tips on minimizing and preventing different types of artifact, check out more episodes of our webinar series, Slide Savvy with Fernando.

- Interested in consultations and feedback? CompuMed’s lead pathologist assistant is available to provide clients with consultations, training and feedback on samples. Contact us to learn more.

- Ready to request a read? Our expert subspecialist network provides some of the most comprehensive, donor-focused biopsy reports in the industry. Take a closer look at what’s included in our reports and how they give transplant centers the confidence to say yes to an organ faster.